If you own a pizza shop your commercial pizza oven is running the show. It produces the very product most of your patrons come to you for. If your shop has a conveyor oven you should be doing daily maintenance to avoid major and costly repairs.

Regular Maintenance

Make sure you are removing and cleaning out the crumb trays below the conveyor belt every night. The impinger fingers in the top of the oven and the conveyor belt should be removed and cleaned thoroughly once a month. More about How to clean your Conveyor Pizza Oven.

Each make of commercial oven has its own instructions, you can visit their websites for an in depth and detailed instructions or review our guide on Middleby Pizza Oven Maintenance.

Four Common Issues

1. The pilot won't start

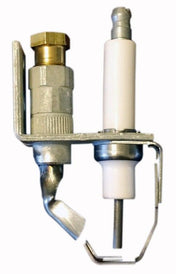

This is probably the most common problem and it is usually the thermocouple that causes this problem. When the pilot lights up and the thermocouple is not directly in the flame it won't get hot enough to allow it to open the safety valve. But if the is directly in the flame and won't stay lit then the thermocouple is probably defective and most likely needs to be replaced as written in 4 pizza oven parts You Need To Stock Now!

2. The oven doesn't reach the proper temperatures

When the oven does not reach proper temperatures then the thermostat is usually the problem. The thermostat may be defective or may be out of calibration. Check the calibration by putting a thermometer in the oven and setting the thermostat to 250°. Open the kick plate under the oven door and watch the burner flame, if it goes off before the oven reaches 250° you might be able to calibrate it.

How to calibrate a thermostat

There are two types of thermostats, a type with a round disk that has two screws holding it in place or a D shaft with a screw in the center. Turn the disc or screw a fraction of a turn at a time and no more than a quarter turn in either direction. Continue turning it a fraction of a turn until you see the burner come back on. If you have reached the quarter of a turn point and the burner still hasn't come back on then the thermostat is defective. If the burner does come back on, watch the oven temperature to see if it gets within 5° to 10° of the preset temperature, if it does you are good to go.

You might have to attempt to calibrate several times for it to properly calibrate. If the burner comes back on but the temperature doesn't get in range then you will need to replace the thermostat.

3. The oven gets too hot

This is also a thermostat problem and requires the same procedures to calibrate as in the above for when the oven did not reach the proper temperature. If calibrating doesn't fix the issue then you may need to replace it.

4. The oven isn't cooking evenly

This problem normally arises after you have installed a new thermostat. The capillary tube with a bulb attached to the end of it is the part that senses the temperature in the oven. The bulb is attached to the clips inside the oven and if this bulb is not put in the same place the thermostat wont register and the oven will cook unevenly.

SyberParts has all the parts you need for your repairs!

Whether you have a Middleby, Lincoln or any other commercial pizza oven, SyberParts has experts ready to answer all your parts and products questions. Fast shipping is included with every order to make sure you get the parts you need no matter if you're in the US, UK (United Kingdom), Australia or anywhere else on the globe.